New product line Vision Systems introduced

IMM, G-Tron and I-Turn now in the portfolio

Huras Stamping Automation expands the product portfolio with the new line HURASZEN and offers with the Vision Systems IMM, G-Tron and I-Turn measurement, testing, and data evaluation in real-time for stamped, turned, and round parts.

All systems are based on modern image processing and can be directly integrated into existing production lines. They instantly recognize form, size, and position deviations, automatically document measurement results, and thereby increase process reliability in mass production.

With the new product line, we strengthen our expertise in the field of automated quality control and offer our customers a complete solution for the digital monitoring of stamping and turning processes.

Vision Systems – intelligent measurement technology for the production of tomorrow.

IMM Measuring Machine

The IMM tests complex geometries in less than two seconds and automatically captures form, position, and profile. With multi-view, digital data evaluation, and repeat accuracy of ±1.5 µm, it is ideal for serial inspections in manufacturing.

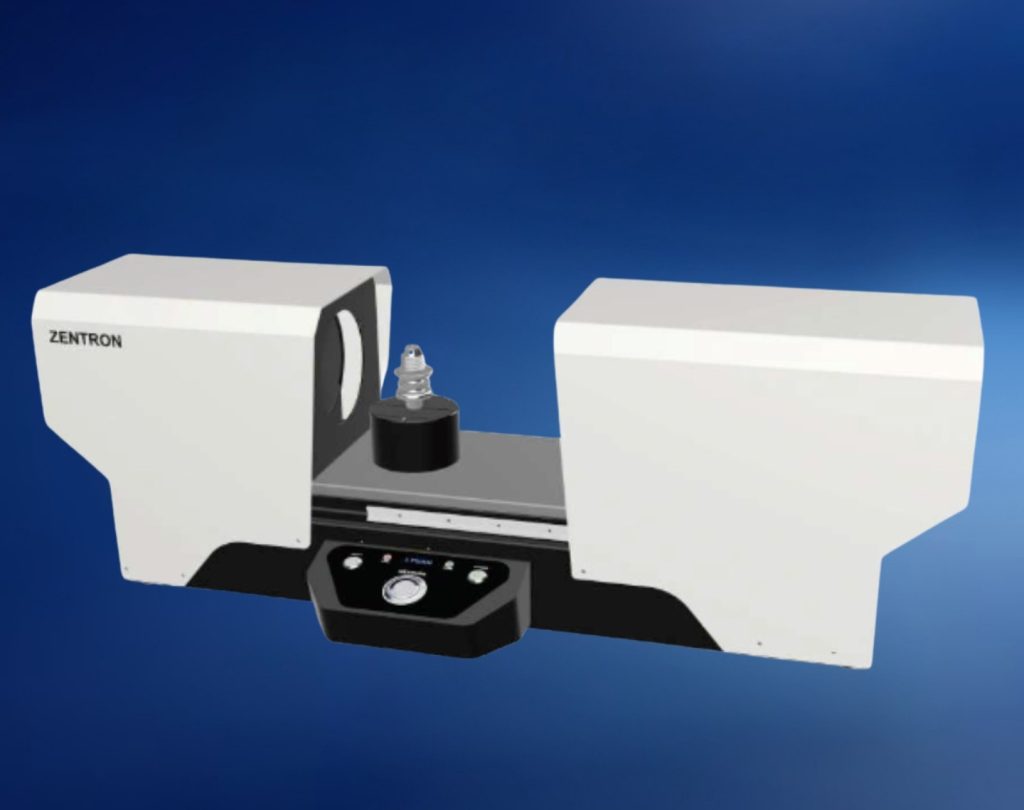

G-Tron Inspection System

The G-Tron monitors stamped parts directly in the line and detects size and form deviations in real-time. With up to three cameras, automatic stop, and integrated data analysis, it ensures 100% control and error-free production.

I-Turn Measuring System

I-Turn measures run-out, diameter, and cylindricity in less than two seconds directly on the machine. The rotating unit captures multiple planes per cycle and automatically exports measurement results to your QS system.