Defective turned parts cause scrap, rework, and machine downtime. I-Turn measures all relevant geometries in less than two seconds and directly displays deviations. We at HURAS Stamping Automation integrate I-Turn into your production, creating a continuous inspection process with documented results and minimal effort.

Short cycles leave little time for manual measurements. I-Turn inspects turned parts directly at the workstation and records runout, cylindricity, diameter and angle in one step. The system delivers measurement data in real time and immediately displays deviations on the screen. Operators inspect parts immediately after processing and avoid downtime due to undetected measurement errors. I-Turn automatically documents each measurement and exports results directly to your QA system or via network to a central database. The solution was developed in cooperation with the company ZENTRON and is exclusively distributed under the name HURASZEN by Huras Stamping Automation in Europe.

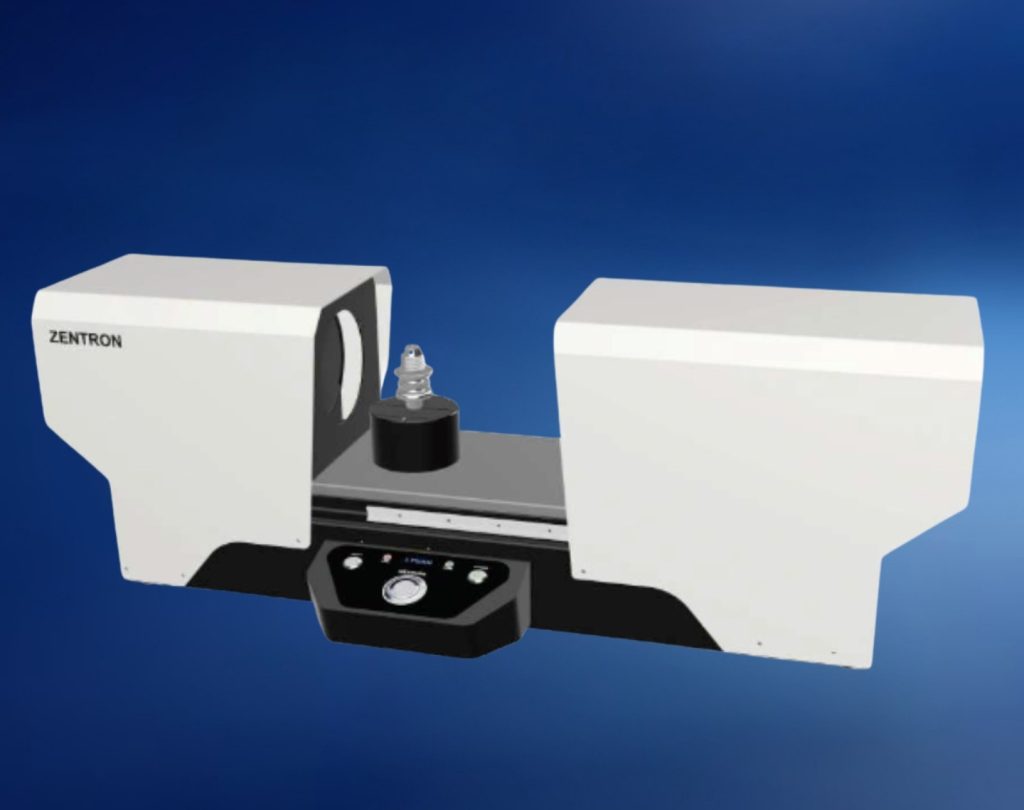

I-Turn operates as a One Touch Inspection System on a tabletop design. You mount the part on the rotating unit and start the measurement with the push of a button. The system captures multiple layers during rotation and creates a complete measurement image with real-time analysis.

The system uses:

The system immediately detects measurement errors and stops faulty processes early. This reduces your material consumption and avoids unnecessary rework.

The repeatability of ±2 µm ensures consistent results over long production cycles. This reduces rework and increases process reliability.

Each part can be inspected and released in less than two seconds. This accelerates batch approvals and reduces wait times between processing and assembly.

I-Turn automatically stores all measurement results with timestamps and part data. This keeps all process data accessible for audits and quality reports.

The intuitive One Touch interface safely guides the operator through the measurement process. New employees can accurately and reproducibly inspect parts after a short introduction.

The maximum part length of 90 mm allows for the inspection of many standard turned parts. With saved programs, you can quickly adapt measurements to new items and remain productive.

Do you want to integrate I-Turn into your production or receive technical details? Contact us for personal advice or request your quote directly.