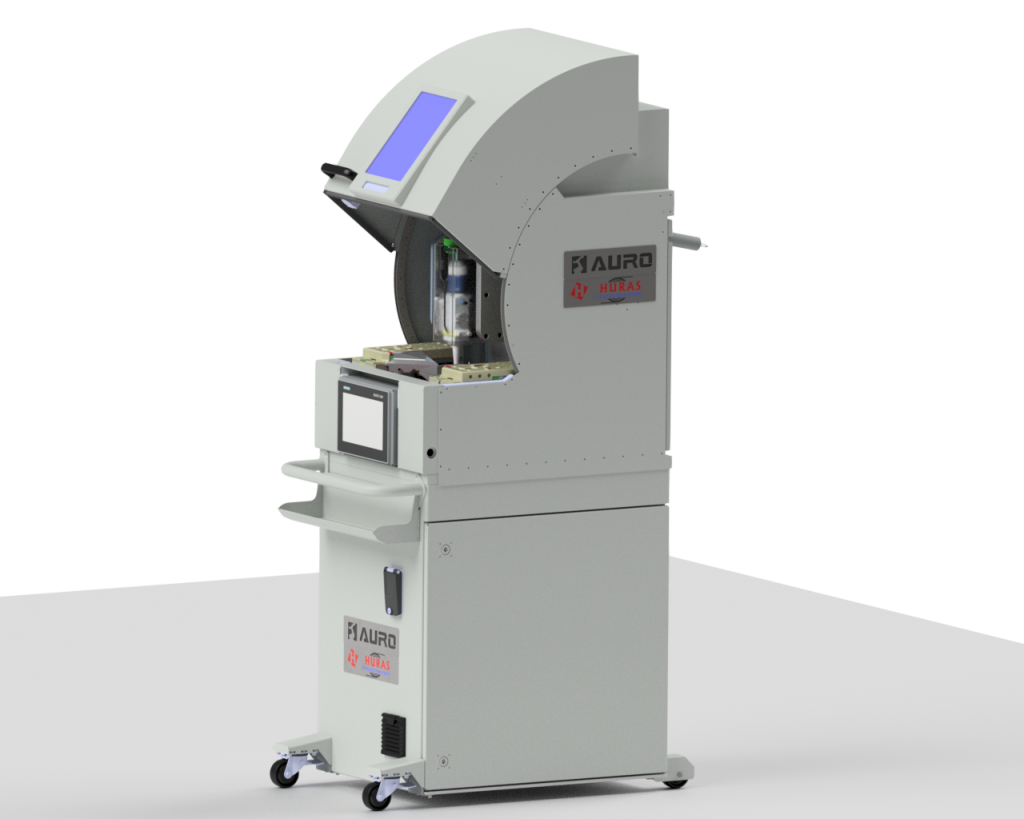

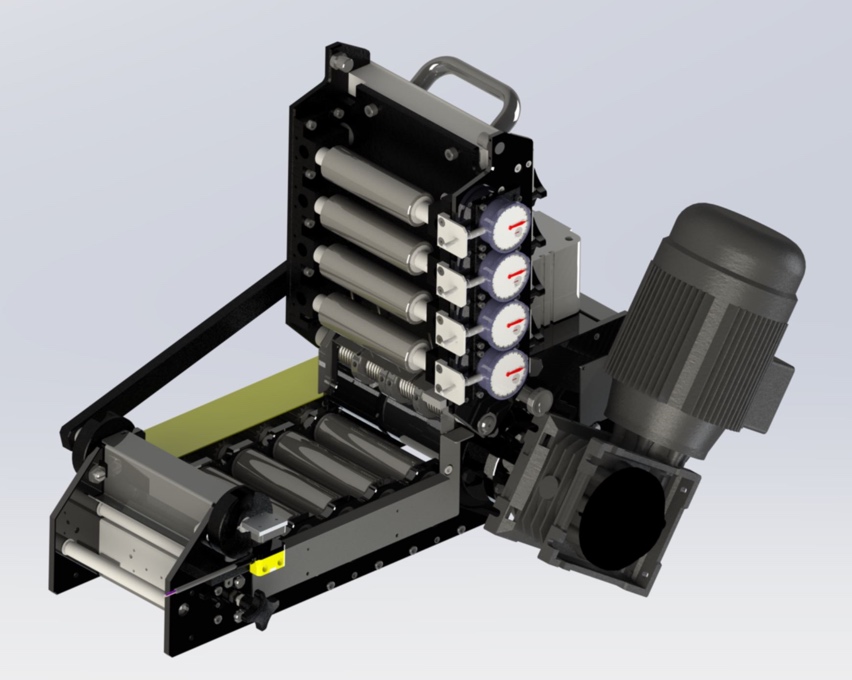

HURAS Stamping Automation develops and implements automation solutions that integrate proprietary machines into complete applications. Whether it’s feeding, stamping process, testing, or assembly: all systems work as a unit. Upon request, we deliver up to the desired interface, mechanically and software-wise coordinated.

HURAS links servo presses, feed systems, test stations, and packaging units into a seamless production process. This results in turnkey systems that reduce setup times, optimize cycle times, and increase process safety.

Examples of combined applications:

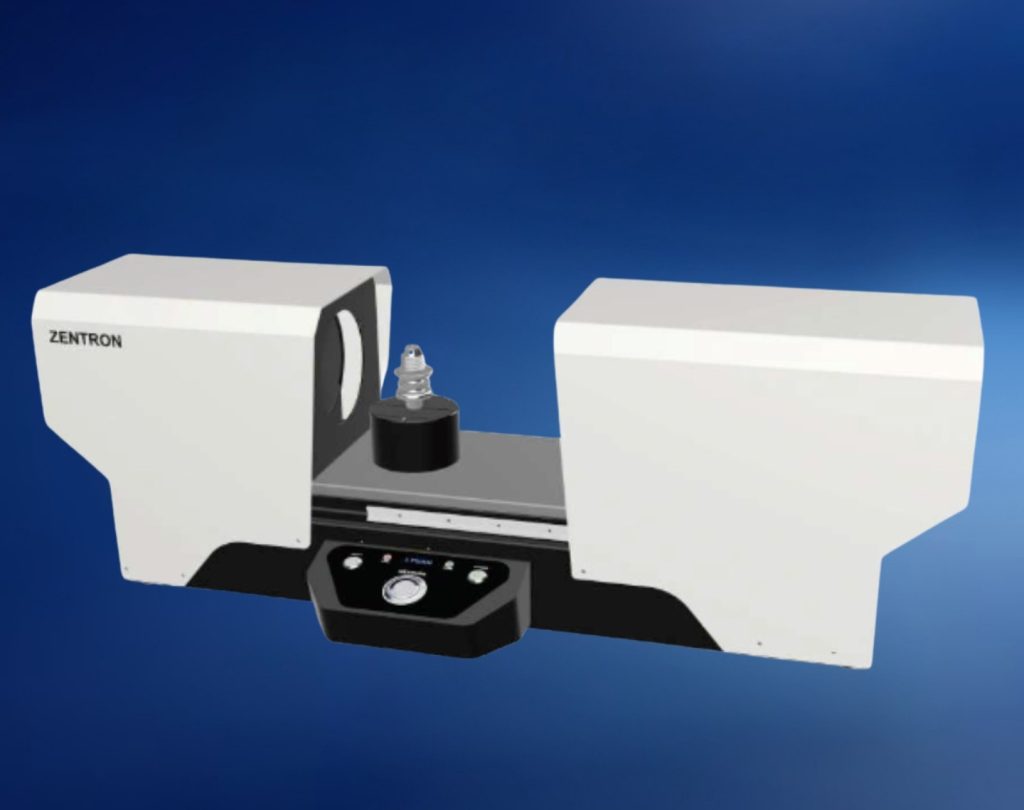

The IMM checks complex geometries in less than two seconds and automatically captures shape, position, and profile. With multiple views, digital data evaluation, and repeat accuracy of ±1.5 µm, it is ideal for series inspections in manufacturing.

The G-Tron monitors stamping parts directly in the line and detects dimensional and shape deviations in real-time. With up to three cameras, automatic stop, and integrated data analysis, it ensures 100% control and error-free production.

I-Turn measures runout, diameter, and cylindricity in less than two seconds directly on the machine. The rotation unit captures multiple planes per cycle and automatically exports measurement results to your QA system.

You are planning an automated line or want to expand your existing processes. Contact us for an individual concept or a technical consultation.